The digitalization of production and management processes can significantly help small and medium-sized enterprises (SMEs) in coping with crisis periods, as well as prepare them for post-crisis transitions. A consortium of institutions involved in the EIT Manufacturing “RIS Industry 4.0 Hubs” project has led an initiative in the form of specialized digitalization seminars and targeted grant support for European SMEs to support them in digitizing their manufacturing and supply chains. CIIRC CTU participated in the project in the Czech Republic with the aim to help the development of local ecosystems. In six countries, more than a hundred companies took part in individualized seminars and 14 companies received direct support and consultations.

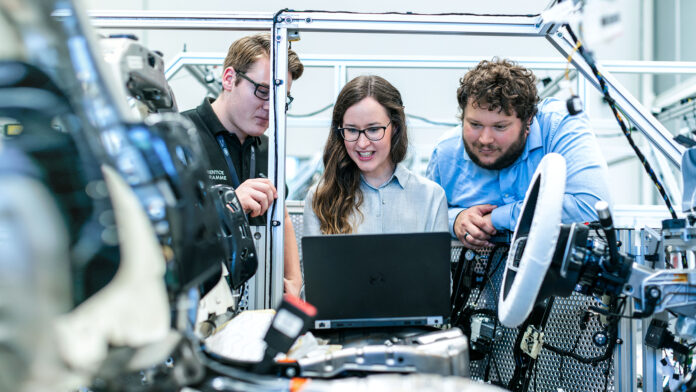

Within the EIT Manufacturing “RIS Industry 4.0 Hubs” (RIS I40H) project, CIIRC CTU together with six more European partners implemented the so-called Regional Innovation Scheme (RIS) to boost innovation capacity and transfer of good practices in European countries that are considered “modest and moderate” innovators. SMEs are encouraged to take advantage of digitalized technologies and improve their digital skills and competencies. For this purpose, the project team organised series of digitalization seminars namely in the Czech Republic, Poland, Lithuania, Slovakia, Estonia, and Greece. The project also provided support to the industrial beneficiaries via an open call, in which companies could apply for mini-grants and get either digital consultations or digitalization plans.

“Within the 12-month RIS I40H project, our team conducted a 3-step methodology that helps SMEs on their way to implementing Industry 4.0 solutions based on digital technologies,” said Alena Burešová, Senior Manager for Industry Research and Development, CIIRC CTU. In the first step, interactive seminars were organised with a proven structure and content that provided introduction of Industry 4.0 technologies to SMEs and served for scanning digital competences of SMEs. Seven seminars in six countries were held and attended by more than 100 participants. In the second step, individual consultations and in-depth evaluation of digital maturity of companies’ operations were provided to navigate enterprises in priority areas for digitalization. The third step consisted in the creation of a concrete roadmap for individual companies, to guide the implementation of particular digitalization plan.

“In challenging times like nowadays, industrial companies tend to postpone the above-mentioned activities although they feel these are essential to digitalize their operations,” added Alena Burešová. “Therefore, as a result of an open call financed by the EIT Manufacturing, we supported 14 SMEs with mini-grants,” explained Burešová.

In the Czech Republic, four companies received either consultancy or digitalization services: For example, the PRESSKAN, a company based in Prostějov operating in sewerage systems for municipalities. “Thanks to the digital maturity assessment, going digital is not just a theory for us anymore,” confirmed Robert Nevrlý, Chairman of the Board of PRESSKAN. “We are now able to search for opportunities and expand our portfolio with solutions that can be used by us or offered to our customers, such as an IoT water level sensoring or an Enterprise Resource Planning (ERP) system for better overview over our operations and facilitation of the work of colleagues on service trips.”

More info: https://ris-i40.eu/results/

EIT Manufacturing is Europe’s leading manufacturing community, one of the newest (established in 2019) of eight innovation communities belonging to the European Institute of Innovation and Technology (EIT). The communities are public-private partnerships, partly financed by the European Union and partly financed by their partners, who include some of Europe’s leading enterprises and research organisations. CTU joined EIT Manufacturing as the only full member from the Czech Republic through two of its parts – the Faculty of Mechanical Engineering (FME CTU) and the Czech Institute of Informatics, Robotics and Cybernetics (CIIRC CTU).