Meet Megi Mejdrechová, a graduate of the Faculty of Mechanical Engineering at the CTU in Prague, a researcher in the robotics perception team at the CIIRC CTU, a winner of the prestigious Werner von Siemens 2020 award in the Industry 4.0 category and last but not least a founder of successful start-up RoboTwin.

Throughout her career, this young woman has been working on solutions in the field of advanced robotics methods combined with computer vision to make it easier for people to work in difficult or even harmful conditions. In the past year, her work and activities have shifted from the pure research field to applied research and industry innovation. She took a step that is often insurmountable for many talented young researchers – she has turned her RoboTwin project, which started as a thesis, into a promising start-up and has started putting her own results into practice. She has not been afraid to take the opportunities she has had along the way. She joined international acceleration and start-up competitions and received mentoring support for both personal and business development. She applied for a project grant and succeeded. Behind many of the key moments was EIT Manufacturing, a community co-funded by the European Union that supports the introduction of innovation into industrial production. Megi Mejdrechová has used many of the tools that EIT Manufacturing offers to young innovators, who may not know about the complexity of services that EIT Manufacturing can offer.

How do you feel about the last two years – was your transition from researcher to entrepreneur planned and gradual or did it all happen quickly and unexpectedly?

It certainly wasn’t planned. When I was studying, I didn’t even think of doing my own project. It all came out while finishing my thesis. The topic was interesting, I enjoyed it very much. I managed to develop a working prototype of a solution for robotizing small-scale industrial painting and coating. But I had no idea what to do with the idea further. I kind of thought someone else might take it on to help the idea and prototype further into the market and production. Eventually, I realized that the only one who could try to do it was me. My current colleague Ladislav Dvořák gave me the idea to apply for the EIT Jumpstarter competition, which targets ideas at a very early stage. That was the beginning of everything else. We won the final of the competition in the Manufacturing category. The condition to receive the prize money was to set up our own legal entity. So we went ahead and founded a start-up of the same name – RoboTwin.

What is the RoboTwin technology about?

With RoboTwin, we responded to a specific industrial need right from the start: the Metalkov an industrial painting company came with the assignment that they needed to robotize production because they were having trouble finding, hiring and training people. However, they found out that they couldn’t do it with conventional automation. The main obstacle is the programming of the robots themselves – in this field their capabilities run up against limits. To make an investment in a robot worthwhile for an SME, the robot must be involved in the production of a complete portfolio of parts. Production in such a company consists of a whole range of parts, and it changes frequently because they do mainly custom production. In addition, the technology of industrial painting and coating is complex and you need to know its principles. A “general-purpose” robot programmer is not able to program robots well enough to produce very complex parts.

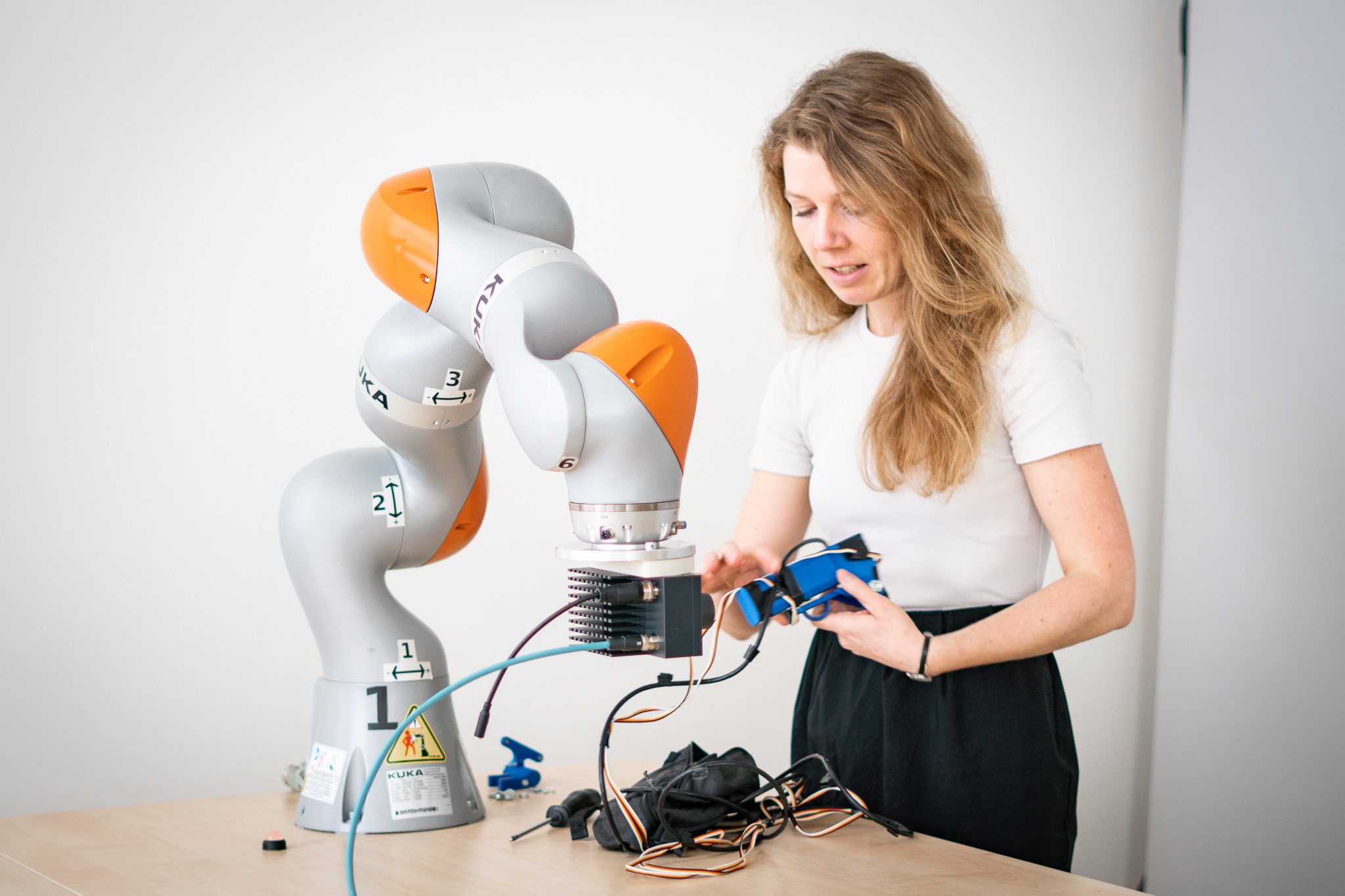

With RoboTwin, we take a different approach to automation. The key for us is not the robot, but the worker, the painter, who is not replaced by a robot, but who we instead integrate into the automation process. The worker teaches the robot. Simply put: A recording device with sensors monitors the movements of the painter’s hand. Our algorithms process the data and automatically generate a program that is uploaded to the robot. The robot is then able to perform the demonstrated tasks and produce the other parts in the series. The workers teach the robots, and the transfer of their technical knowledge and know-how is essential. This approach is otherwise lost in conventional automation. In addition, we are also able to robotize highly complex parts, so typical of small series production. The process is fast, easy, efficient, and involves the worker.

Your journey with EIT Manufacturing has really taken you through a series of programmes – from the very beginning in EIT Jumpstarter, to winning ViennaUP, to the successful project in Call for Proposals 2023. How would you describe these moments for someone who is at the beginning?

We are an EIT Manufacturing baby in the innovation field. This is because our innovation fits in with their goals and vision. We’ve been through a lot of their events and programmes over the last two years, especially the mentoring ones. We’ve gained a lot of experience and enjoyed it. Gradually, we built our own vision of what our product and the company should look like in the future. At the EIT Jumpstarter we met Jasmin Popovska, who works as Investment Manager at CLC East in Vienna, which is the co-location centre and headquarters of EIT Manufacturing for Eastern Europe. She and her colleagues are business experts and consultants who have extensive experience in the start-up environment and in transforming ideas and innovations into industry. They connect corporates, start-ups and investors.

What came next?

After the EIT Jumpstarter, we continued through the ViennaUP startup festival. EIT Manufacturing has one of its programme blocks there. We participated in the BoostUp competition for Eastern Europe. Our idea caught the eye and we got more individual mentoring as a result. This was focused on building and validating a business plan to commercialize our product. Thanks to the mentoring, we know how to prepare a financial forecast for the next years – Profit & Loss, how to plan Cash flow and so on.

You have been involved personally in RIS LEADERS for Female Founders. What was it like?

It’s a project that supports women and girls in business and tech. As part of that, I was in a mentoring program for women with specific ideas for innovation in the industry. That was great and I learned a lot – like how to present a project to a jury. We practiced „pitching“ so that we could say the main thing about our innovation in a catchy and interesting way. The program ended with the Best Woman Innovator competition, in which I succeeded and won a financial prize. It helped us a lot to balance the beginning of our business.

After the EIT Manufacturing programs abroad, we got into the Czech accelerator „Start it @ČSOB“. We are getting to know the nature of doing business in the Czech Republic and we the mentoring focuses more on the specifics of the Czech market.

Who makes up the RoboTwin team? Is it just you or do you have other teammates? And what are their roles?

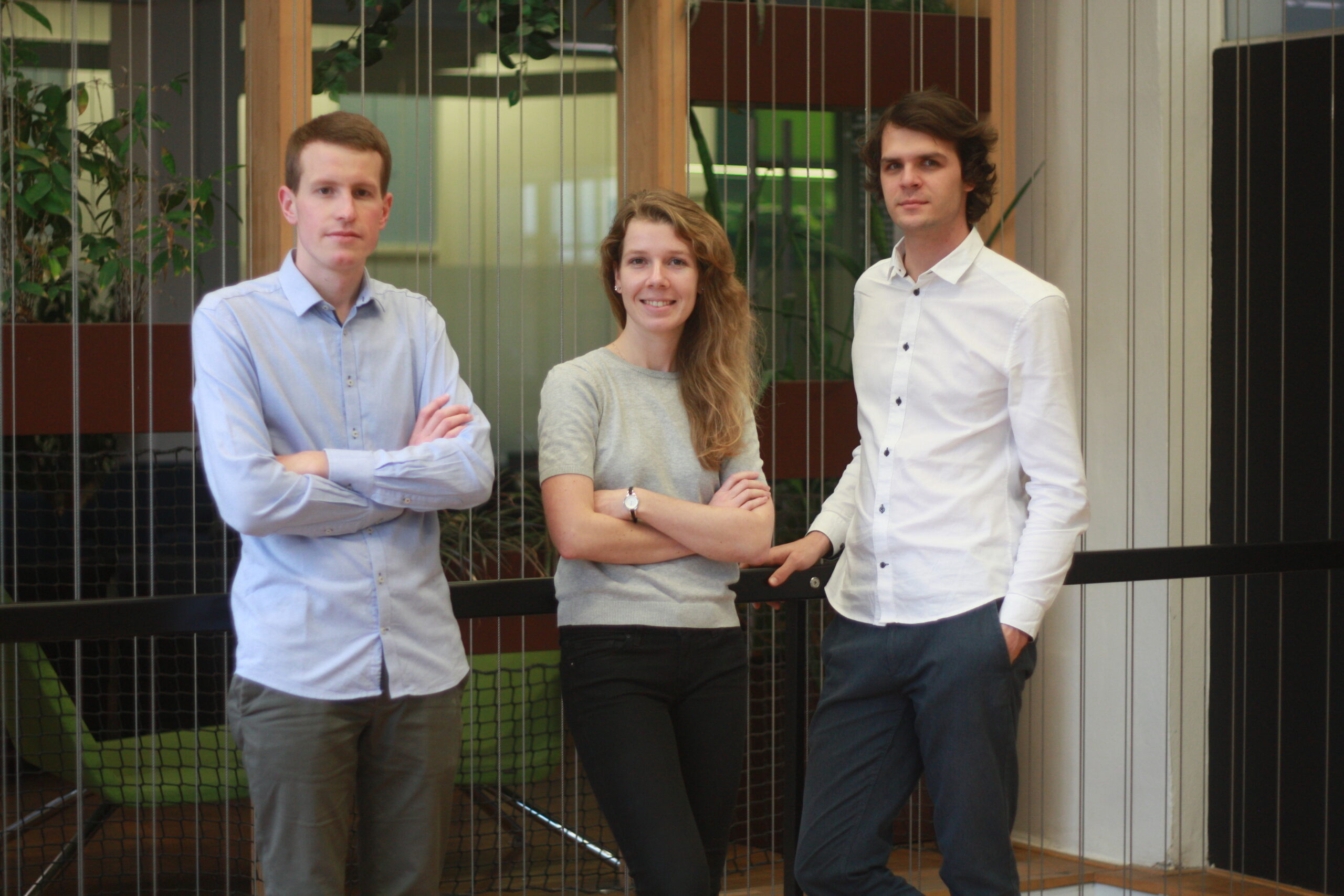

We are three founders, we met during our studies at the Faculty of Mechanical Engineering at CTU during a semester abroad at NTU in Singapore – me, Láďa Dvořák and David Polák. We got together during the EIT Jumpstarter. I had the initial idea, the prototype, the product. But I didn’t have the right entrepreneurial „drive“.

It’s very important to have someone with entrepreneurial intuition on your team. I needed to surround myself with people who had business intuition and could plan. It’s also important to communicate with the industry and be able to test and integrate ideas into production. David is the one who is focused on that. He knows how to find partners and he’s not afraid to approach them. The most important thing is that we’re all on the same page. We share a determination to get things done, we’re personally motivated and we enjoy it.

How did RoboTwin move from a thesis topic to an innovation project supported by EIT Manufacturing?

I think our project shows how well innovation support programmes can work. We are not only addressing the need of one customer, but we are developing a solution that will be applicable to many other manufacturers. This will enable the scalability of robot programming. Thanks to the funding, our initial idea can reach the next stage of feasibility on a larger scale. It’s not just a solution for one company, but will be available to other manufacturers as well. We couldn’t have done it on our own and one company wouldn’t have paid for the solution. Joining the EIT Manufacturing programme helped our innovation have a real impact in the industry. It has also opened the door to a number of partners. This is very important, without partners we would not be able to make it happen.

Who are your partners?

We have managed to put together a good consortium of partners. We have the support of CIIRC CTU and access to great people and equipment. We have the support of our Italian partner Cefriel with a lot of experience in productizing. They help us to design the final product so it can be successfully launched on the market. On top of that we have business mentoring to ensure that the project continues and has an effect for other companies. This is provided by the Industry Innovation Cluster from Slovakia. There is a wide range of competences in the EIT Manufacturing network, and we have taken advantage of these opportunities and built a consortium according to our needs. This is complemented by two end users of the RoboTwin solution, in our case two Czech companies – the integrator GALATEK and the industrial coating company Dikrt. We consult and test the product with them. We are glad that their managers decided to come on board with us, at a stage when we are still developing the final product.

ow do you perceive the experience in the research environment you came from? Does it help you with your own project?

We are a technology company, we make a technology product. We know that we can try our best and still things can go wrong. A problem may arise during the process, you don’t know about it at the beginning of development. The current technological state can stop us or divert us from the original plan. That’s why I’m so grateful to work with CIIRC researchers to help us solve such challenges. We benefit greatly from their expertise. They help us with robot control, sensors and scientific methodology. For example, we are now testing the sensors and we can decide which sensor is the right one according to our criteria. And that’s where Professor Hlaváč’s team is so valuable because they have experience in the systematic scientific work that is needed to test hypotheses.

Personally, I hope that the collaboration is beneficial for the scientists as well. While working with us they get a new perspective on their work from a production point of view. For many institutions, an applied project is not so common. We don’t focus on publications, we are actually creating a product. We focus on what companies need and how to do it with an industrial application in mind.

What was the evolution of your cooperation with CIIRC CTU?

I have worked with Professor Hlaváč before. When I was finishing my master’s degree at the Faculty of Engineering, I was very interested in machine learning and I wanted to do more with it. Even as a student, I worked in his department. That’s how I got into robot learning tasks using machine learning and continued there for another year after graduation. Then I moved away from research for a year into the commercial sector and software development. I’ve come back and I’m very happy that we can continue working with the CIIRC team.

What is a goal for RoboTwin for this year? What will be the outcome of the project supported by EIT Manufacturing?

We entered the EIT Manufacturing project with a prototype. Our goal is to move the prototype from TRL 6 to 8. In other words, we will have a product and we will bring it to market and into real production. We want to take our innovation from the development lab to the coating industry. In parallel with product development, we are also working on a marketing and commercialisation strategy. We are developing the product and the company as a whole. This fits exactly into the plans we had and needed to implement a year ago when we applied for the EIT Manufacturing project.

What are your next plans and what do you see as the biggest challenge?

The current challenge, I’m looking forward to, is attending the European Robotics Forum. We will be presenting RoboTwin to the European robotics community and also finding out where the technology is moving as we want to keep up with the latest trends. The short-term mission is clear for us – to take the product and get it to the market. In the more distant future, we plan to expand from industrial painting and coating to other production segments. The issue of programming and learning robots is ubiquitous and acute for smaller manufacturers. This can target segments such as industrial bonding, welding, and related quality control. We have plans for further expansion.

Prepared in co-operation with EIT Manufacturing Hub Czechia