While the Czech robot WLTR is slowly becoming a symbol of automation in construction, few realize that its brain was largely developed at the Czech Institute of Informatics, Robotics and Cybernetics. It was here that the team from the Intelligent and Mobile Robotics Laboratory developed a key part of the software that enables the robot to do something crucial: to „see“, „decide“, „plan“, and „act“. Without this, the Bricklaying robot would remain just a massive piece of metal.

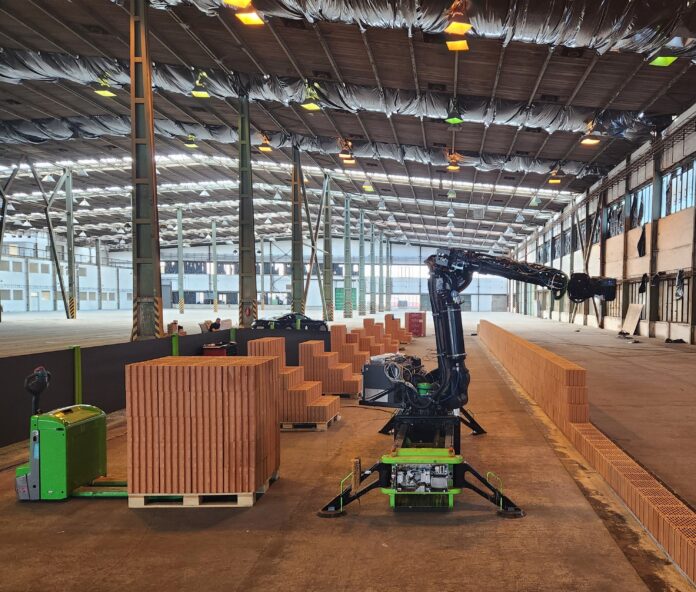

The Bricklaying Rŕobot is a fully autonomous robotic system capable of receiving a wall construction task and starting work immediately—without scaffolding and without breaks. It performs masonry tasks with better-than-millimeter accuracy and at a speed equivalent to the work of 5–6 human workers. At first glance, it seems simple: the robot picks up a brick, places it correctly, and continues. In reality, it’s an extremely complex process mastered by CIIRC experts—Libor Přeučil, Karel Košnar, Gagel Ecorchard, Jiří Dolejš, and others.

The CIIRC team developed the following key components:

-

Visual localization of pallets and individual bricks

The robot must first „find“ the bricks, which are not neatly aligned, vary in size and color, and are often covered in dust, mud, or exposed to rain. Additionally, their shape and dimensions are often worse than the required precision for handling them. -

Precise arm guidance for gripping and placing bricks

It’s not enough to just aim. The robot must determine the correct grip, compute the trajectory, adapt to real-world conditions, and deliver the brick precisely into position within the wall. -

Motion planning and coordination

The robot arm’s movement is planned and optimized from several variants to choose the best trajectory. It must not collide with the structure, construction materials, or itself. Moreover, its work must be synchronized with other machines operating on-site.

Each of these steps results from complex algorithms running in real time. Developing a robust system capable of functioning outside the lab under harsh real-world construction conditions was one of the project’s greatest challenges.

Bricks on-site are not uniform. Some are slightly deformed, dirty, or hard to detect. In the lab, this is manageable—but on a construction site, it’s a serious issue. High-precision sensors that work well in controlled environments often fail outdoors.

“Even a seemingly simple task like planning how to grip a brick is actually a complex mathematical problem,” says Libor Přeučil, head of the CIIRC team. “We had to create a system that’s smart enough, fast enough, and—above all—reliable enough in operation to compete with human bricklayers.”

From research to practice: from CIIRC to KM Robotics

The software was developed as part of a joint project supported by the Technology Agency of the Czech Republic (TAČR Trend): Research and development of a robotic system for automated bricklaying using clay blocks, project number: FW03010304. After its successful completion, part of the software rights was sold to Wienerberger and KM Robotics. These companies now replicate and deploy the robots under the startup GreenBuild.

The WLTR system has already proven itself in the Czech Republic, Austria, and the United Kingdom. While the physical construction of the robot was done elsewhere, its ability to handle constant uncertainty on a real construction site—and to think and act autonomously—comes directly from CIIRC CTU.

European recognition for technology transfer

The results of the collaboration between CIIRC, KM Robotics, and Wienerberger have been recognized by the European robotics community. The WLTR bricklaying robot project won a prestigious second place in the 2024 euRobotics Technology Transfer Award, which honors the best examples of successful research-to-industry transfers.

The competition takes place within the European Robotics Forum (ERF), the most significant European event for robotics and related technologies. The jury was impressed by how research into visual localization, motion planning, and autonomous manipulation was transformed into a fully operational system with the potential to fundamentally change the construction industry.

“We are immensely proud to have received this prestigious award,” said Libor Přeučil, head of the Intelligent and Mobile Robotics Laboratory at CIIRC. “This recognition confirms that we have a rightful place in advanced robotics and cybernetics and that we can lead fundamental research and successfully develop technologies with real-world impact based on it.”