The National Center for Industry 4.0 in cooperation with Škoda Auto, Technologická gramotnost and the RICAIP Testbed for Industry 4.0 CIIRC CTU – organized the second series of practical workshops for primary and secondary school students this year. Their goal was to let the students literally touch and try new technologies and present them what their dream job could look like.

Although the generation of people born in the third millennium literally grows up with a mobile phone in hand and it might seem that their relationship with technology is more than friendly, the iGen, i.e. the digital generation, still has a vague awareness of how interesting, diverse and creative can be work in technology, industry and related fields.

„Almost everyone wants to be an influencer today, but technological workshops confirm that the possibilities hidden by technology are unfathomable,“ says Robert Keil, director of the National Center for Industry 4.0, which patronizes the workshops. „In Testbed for Industry 4.0, students had the opportunity to meet the results of bachelor’s or engineering theses and their authors. It’s literally an eye-opener and inspires you to orient your career path in that direction,“ adds Keil.

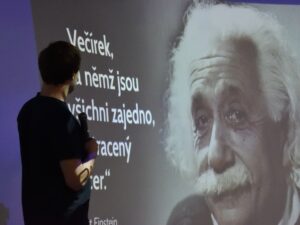

The first part of the program is designed as an interactive lecture that presents basic terms and information that can help you navigate the field in a comprehensible, entertaining and clear way. The Technologická gramotnost has a highly tuned program that is always adapted to the age group of pupils and students in the auditorium.

„If we really want to become a „production“ company and not just an assembly company, then we have to start doing something. And the key to that is to focus on the younger generation. That’s why we consider it important to encourage interest in technical fields among students and show them that technology is cool and sexy,“ says Tadeáš Salaba from Technologická gramotnost, who organizes lectures for students.

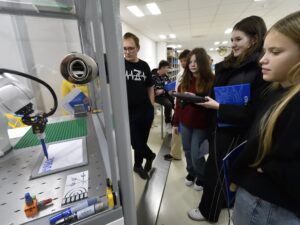

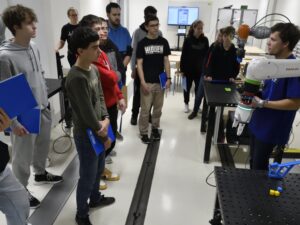

The unique connection to the technological infrastructure of the RICAIP Testbed for Industry 4.0 adds a practical dimension to the lectures. In the second half of the program, students can test and try out everything they have heard about here: for example, a collaborative robotic workplace for human-robot cooperation during assembly, where the robot is able to respond to the immediate needs of the operator, or a robotic cell that autonomously disassembles old car batteries and prepares them for recycling. Attention was also drawn to the flexible production line, where the supply of parts for production is carried out by means of automatically controlled trucks (so-called AGVs). In the lower part of the testbed, the so-called heavy part, students will find not only giant robots that are used for machining, but also technologies for 3D printing or laser use.

Foto: Roman Sejkot, CIIRC ČVUT